PRODUCT DESCRIPTION

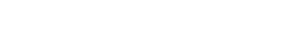

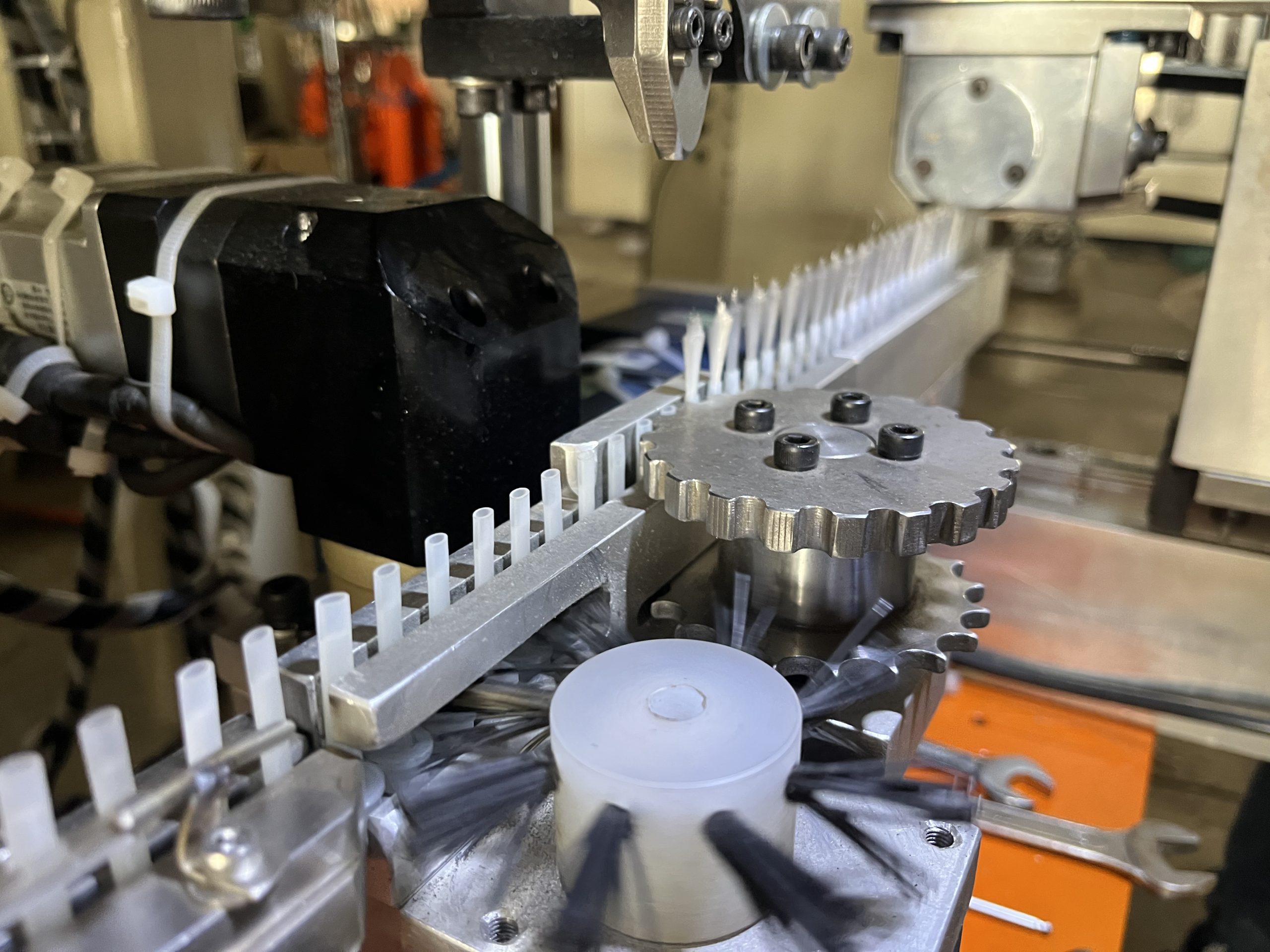

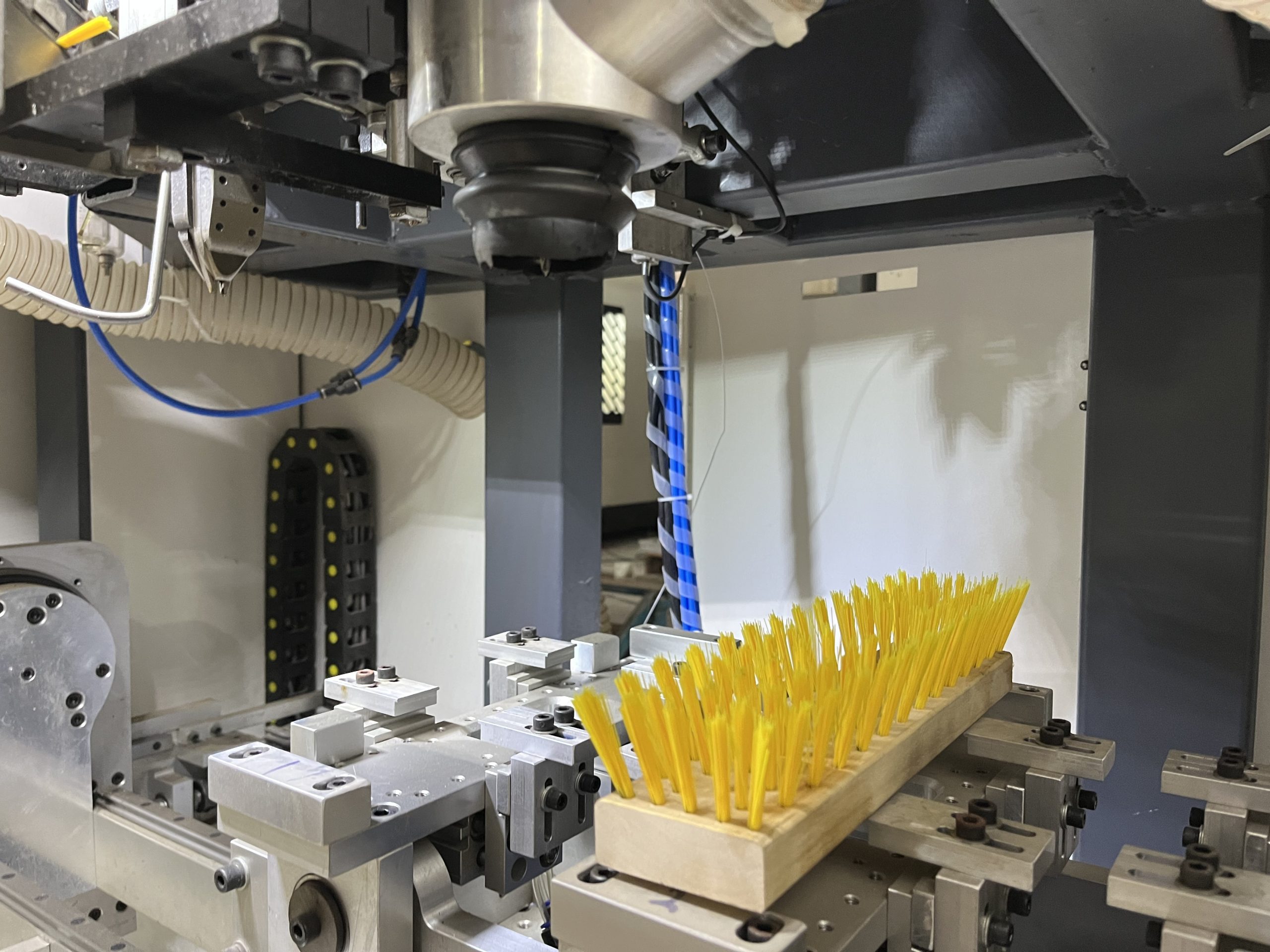

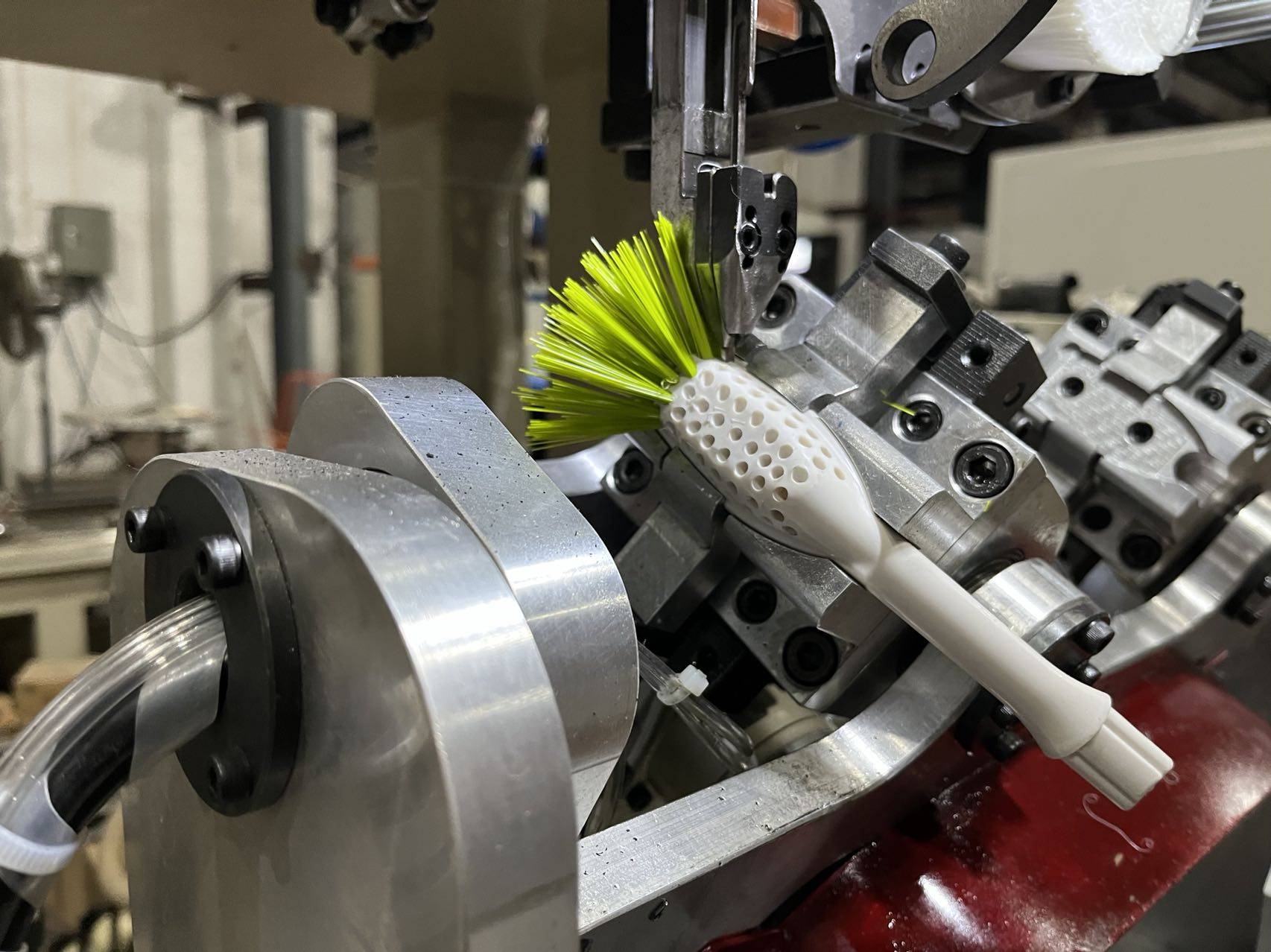

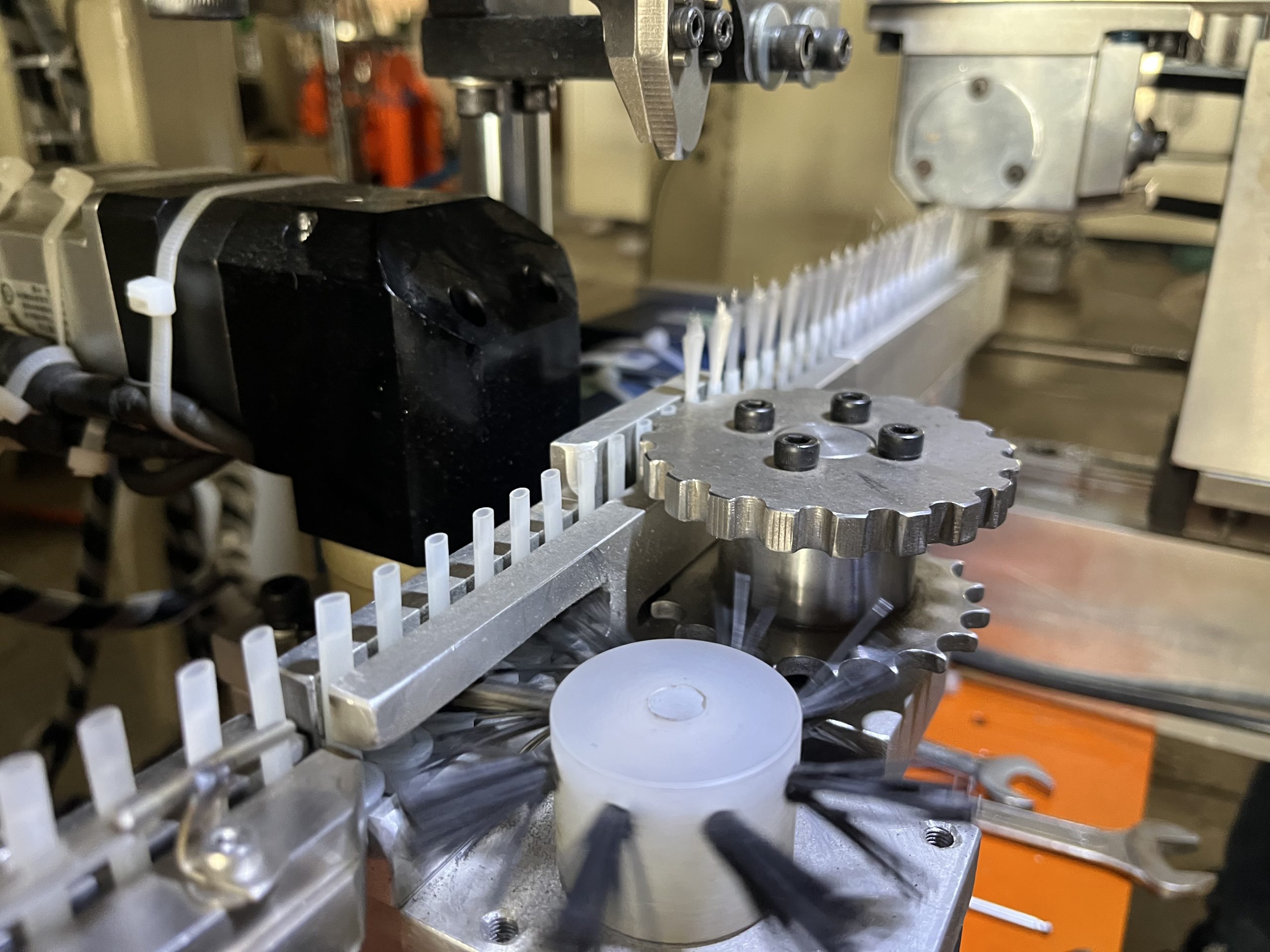

Industrial disc brush machine is used for the production of various types of disc brush brush machine, the machine can be customized according to the customer’s brush needs to suit customer requirements of the industrial disc brush machine, industrial disc brush machine includes 2 axis 1 drillling and 1 tufting/filling machine, 2 axis 2 drillling and 1 tufting/filling machine, 4 axis 1 drillling and 1 tufting/filling machine, 4 axis 2 drillling and 1 tufting/filling machine, 5 axis 1 drillling and 1 tufting/filling machine, 5 axis 2 drillling and 1 tufting/filling machine, industrial disc machine can match to different angles, different filament/fiber types, different filament/fibe lengths, different disc sizes, different disc hole sizes, different disc materials, etc.

The disc base can be made of various materials such as plastic , aluminum, wood,and composite materials. The bristles or filaments on the disc brush can be made of different materials, depending on the application. For example, nylon bristles are commonly used for cleaning and deburring, while abrasive filaments are used for surface preparation and finishing. The density and length of the bristles can also be varied to achieve different results.

Industrial disc brushes are used for a industrial and commercial of applications, including deburring, cleaning, polishing, and finishing,cleaning, sanding, polishing, decontamination, rust removal and surface coating. Overall, industrial disc brushes are a versatile tool that can be used in a variety of industries, including aerospace, automotive, manufacturing, and woodworking.